Quick Guide to Precision Measuring Instruments

April 26, 2021What is Ultrasonic Thickness Gauge?

In the renowned industry of testing and measurement, the process of ultrasonic thickness measurement is a typical method of non-destructive measurement performed on the substance to measure thickness of it based on the ultrasound wave from the device.

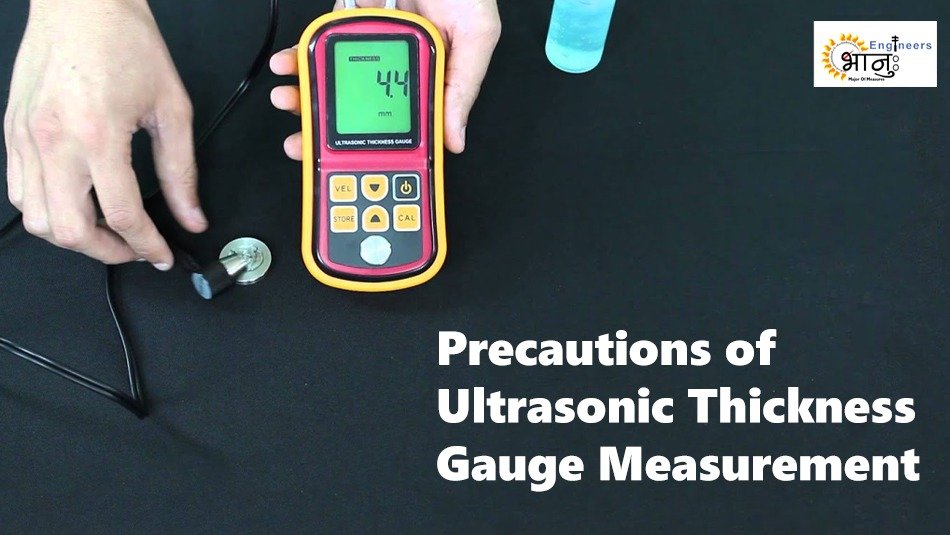

Precautions of ultrasonic thickness gauge measurement:

Thickness measurement done by ultrasonic thickness gauges require extra detailing and obviously a lot of precautions, today we will focus on the issues that you need to focus on before measuring through the process of ultrasonic thickness measurement

1. Choose the right speed:

An inappropriate selection of speed might stand as a threat for obtaining correct readings of ultrasonic thickness measurements. Before measuring your substance, you have to previously set its speed of sound based on the type of the material. Otherwise this can destroy the entire method and give you a false calculation.

2. The correct use of coupling agent:

A proper layer of coupling agent is very much required between the measuring probe of the device and the plate of the same. This agent is typically used to exclude the air between the probe and allows the object to be measured by giving it a space, leading the ultrasonic wave effectively calculating the thickness. If the coupling agent is by chance type selected incorrectly, it will leave the device unmeasured.

3. Temperature influence on the material: :

The ultrasonic measurement and its propagation speed are deeply impacted by the temperature. If the temperature is not set at the right point if it is too high the temperature will block the measurement, however one can solve this through a test block comparison method which allows the temperature compensation coefficient to be obtained.

4. Pay attention to the surface roughness of the probe:

If the particular probe is used for a longer period of time, the roughness in the surface of the material continues to increase, leading to a notable amount of decrease in the sensitivity of the probe which provides an incorrect display. Therefore, it is very important to always be very aware of the surface roughness of the probe only then you can get the proper results in ultrasonic thickness measurement.

Final Words:

Does not sound so simple right? We know; hence we have a permanent solution for you. Bhaanuh Engineers the leading testing and measurement equipment in India are now providing a professional guide to you while you perform this ultrasonic thickness measurement in your industry. Their experts will thoroughly make you understand everything, every safety measure and the precautions you need to go through to perform an accurate thickness measurement. Bhaanuh Engineers is one of the celebrated testing and measurement equipment suppliers in India who also tends to provide their customers with a varied and wide range of ultrasonic thickness gauges which are especially tailored for every unique client and to cater their needs for their every unique industry.

So why wait, check out their range now and happy measurements.

Follow the link to shop from them, now: